Description

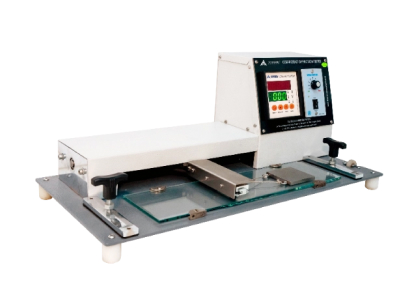

This kind of instrument can be used to test the melt flow rate(MFR) figures of all kinds of plastic and resin in the viscous flow state. It is not only suitable for the high melting temperature engineering plastics of polycarbonate, polyarylsulfone , fluorine plastic and nylon but also suitable for some other low temperature plastic products which are made up of polyethylene(PE), polystyrene(PS), polypropylene(PP), ABS resin, polyoxymethylene(POM) and polycarbonate. So it is not only widely used in the plastic production, petroleum and chemical industry but also in the relevant institutions such as scientific research units and the community inspection departments. The melt flow rate instrument is suitable for measuring the thermoplastic melt mass flow rate following the determination in the standard ”GB/T3682-2000 thermoplastic melt mass and volume flow rate measurement”. The standard is equivalent to the requirement in the ISO 1133:1997 and can meet the ASTM D1238 test. Considering the beautiful appearance and convenient operation ,the desktop structure of the melt flow rate instrument makes the equipment performance reliably and stably. Besides, the high-precision control instrument using fuzzy PID algorithm for temperature control has the feature of high sampling precision and high speed control.

Product Advantages

- Fast heating speed with minimal overshoot

- High precision of constant temperature

- Quick restoration of constant temperature after packing

- Convenient test parameter calibration and correction

- Optional manual and automatic cutting test methods

- Equipped with an LCD working platform

- Automatic printing of test results with an included printer

Technical Parameters

| Extruding and Discharging Part | Outlet diameter | Phi * 2.095 ± 0.005 |

| Outlet length | 8 ± 0.025 | |

| Charging cylinder diameter | 09.550 ± 0.025 | |

| Charging cylinder length | 152 ± 0.1 * mm | |

| Piston rod diameter | 9.475 ± 0.015 * mm | |

| Piston rod length | 6.35 ± 0.1 * mm | |

| Temperature range | RT+5-400°C (500°C optional) | |

| Constant temperature accuracy | ±0.5°C | |

| Minimum temperature displayed | 0.1°C | |

| Cutting method | manual or automatic cutting | |

| Temperature recovery time | less than 4 minutes. | |

| Printed | Supply voltage | |

| A mini printer is used to print output automatically | AC * 220V plus/minus 10% 50HZ | |